What Boston Dynamics’ Atlas reveals about the future of NdFeB magnet demand

World’s first enterprise-grade, industrial humanoid robot

At the CES 2026 technology showcase in Las Vegas, robotics maker Boston Dynamics unveiled the latest version of its Atlas humanoid robot, which is now in commercial production for a select number of early adopters.

The humanoids are integrated with Google’s DeepMind AI models and can perform complex, human-like tasks such as lifting, sorting and material handling on factory floors, order fulfilment centers and beyond.

Hyundai Motor Group, majority owner of Boston Dynamics, announced plans to establish a production system capable of manufacturing 30,000 robots annually by 2028. Early last year, Hyundai revealed its intent to deploy tens of thousands of robots at its factories “in the next few years”.

The 1.9m (6.2 ft) tall machine will have battery life of 2 to 4 hours after which it autonomously navigates to a charging station, swaps out its own battery in 3 minutes and gets back to work.

According to Boston Dynamics, “every centimeter of Atlas is meticulously designed, manufactured, and calibrated as the world’s first enterprise-grade, industrial humanoid robot.”

Atlas possesses an impressive 56 degrees of freedom (DoF), double that of some incumbents, that allow it to move around and operate in the same workstations using the same tools and equipment existing staff use.

For comparison, the original Atlas released by Boston Dynamics in 2013 had 28 DoF while the karate-kicking, backflipping G1 humanoid produced and sold today by China’s Unitree has 23 to 43 DoF. Earlier humanoids like Honda’s ASIMO in 2000 had 26 DoF while the WABOT-1 developed by Waseda University in 1973 had just 7 DoF.

According to Boston Dynamics, “Atlas ships with physical intelligence out of the box and can be customized for your application in less than a day.” Atlas comes ready for a range of warehouse and factory tasks, from part sequencing to machine tending, order fulfillment and beyond.

And the coolest part: as soon as one Atlas learns a new skill, that task can easily be deployed across an entire Atlas fleet, driving tangible impacts fast for commercial users.

Rising DoF: Implications for NdFeB magnet demand

In relation to NdFeB magnet demand, Atlas evinces an important trend that we’ve repeatedly flagged over the last two years: rising degrees of freedom over time are driving increasing motor and magnet use per average robot.

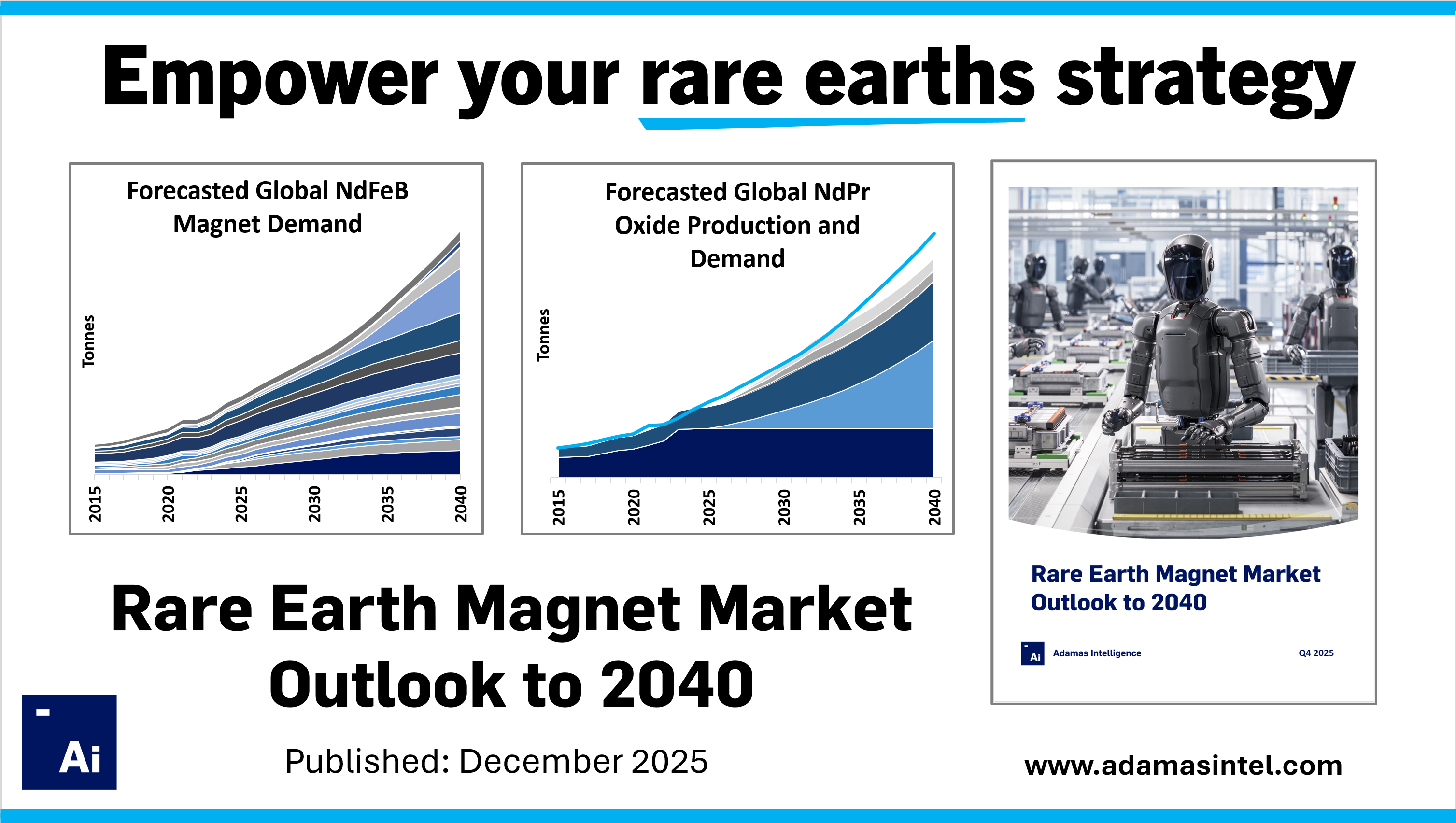

From our latest Rare Earth Magnet Market Outlook to 2040 report:

“The average humanoid robot developed to-date exhibits around 30-40 degrees of freedom (enabled by ~30-40 motors and actuators). Going forward, we expect that number will increase closer to the number of human joints (i.e., 78), enabling greater freedom of motion, higher motion complexity and an ability to tackle a wider range of potential applications.“

From our 2025 whitepaper, titled Humanoid Robot Revolution: NdFeB Supply Chain Implications and Strategies:

“This escalation directly boosts demand for NdFeB magnets, critical for the high-torque, compact designs of these motors.“

Evolving hands: Implications for NdFeB magnet demand

Late last year, Boston Dynamics unveiled rugged three-finger grippers for Atlas that featured seven DoF and seven actuators a piece, along with tactile sensing in the fingertips and cameras embedded in the palms.

At CES, attendees saw a prototype of Atlas carrying out tasks with the grippers along with a display version equipped with smaller four-fingered hands. The robot’s field-replaceable limbs are designed to use swappable end-effectors specialized for the task at hand.

In an insight we published last year looking at the potential of robot makers to widely implement swappable end-effectors rather than fixed human-like hands, Adamas research associate, Meg Black, concluded that the future will likely entail a combination of both approaches.

“In any scenario, be it fixed hands or specialized snap-on tools, the future of robotics continues to bode well for NdFeB permanent magnet demand. Ultimately, if a large portion of robots developed in the future come complete with an assortment of accessories for different tasks, as opposed to fixed human-like hands, it could translate to even greater demand for motors, actuators, and rare earth magnets per robot than previously expected.“

Key takeaway: Demand growth a function of compounding forces

Ultimately – the key takeaway here is that future NdFeB magnet demand for humanoid robots will not be driven by robot unit sales alone, it will be driven by the compounding of unit sales growth, increasing degrees of freedom and, in at least some cases, the inclusion of a wide array of NdFeB-containing end-effectors and tools per robot.

As such, Adamas continues to forecast that robotics are the new frontier of medium- to long-term NdFeB demand growth and expects the sector will surpass all other end-uses and applications by 2040.

A must-have resource for anyone with a professional interest in the mine-to-magnet supply chain

Empower your organization to seize opportunities and navigate risks with the latest, most comprehensive industry analysis, market data and forecasts available.

Our new Rare Earth Magnet Market Outlook to 2040 report is a must-have resource for project developers, miners, processors, metal makers, magnet makers, end users, institutional investors, government agencies and other stakeholders with a professional interest in the mine-to-magnet supply chain.

Contact us for more information about the new report and our other industry-leading services.